Everyone should read

Capital in the 21st Century by T. Piketty. I do not care if you have to sit here for 5 years with a dictionary and 5 economics texts and puzzle it out word by word, sentence by sentence and chapter by chapter, you should read it. And by "read", I mean really think about it doing the math for all of his cases your self to make sure you understand what he is saying, and then doing the math for the cases that he does not address.

Core to Piketty's arguments is the Victorian idea that some deserve to be rich. This gives them the right to underpay workers, take natural resources, and otherwise do whatever was necessary to get rich. America was opened up by trading companies that exploited the natural resources such as gold, cod, and beaver. The kings of France and Spain got rich as did the Hudson Bay trading company, but the trappers, fishermen, and soldiers got very little. However, the real wealth extraction and capital formation came with the building of the US railroads, and men like Carnegie, Rockefeller, Dupont, Huntington, Morgan, Gary and their ilk.

These men were just greedy - in many ways, true sociopaths. The underpaid their workers, and by extension the worker's families. They were willing to defraud the US government, and by extension all other taxpayers. They stole federal land by enclosing it so there was no access. They failed to pay royalties on timber, grazing land, and mining. And, they disposed of their waste in ways that imposed costs on others. Ultimately, this cavalier waste disposal will drive AGW, which will cause more dollar damage to the rich than to the poor.

They were rich, and therefor admired and lionized. Society came to admire the "tough' business man that could get the deal he wanted. They were followed by another generation of corporate managers such as Sloan, Kaiser, Watson, and Hughes.

Corporate managers were considered the heros of the capitalistic economic system, even when they sent coal miners down into the mines without medical benefits or even fair prices at the company store. Overall corporate managers were cavalier about proper disposal of waste - including CO2 from all industrial processes.

All of this created enormous wealth, much of which is now held by the 1%.

However, much of that wealth formation involved the release of CO2 into the atmosphere. We made things using the energy from coal and tossing the CO2 into the sky. We used oil to transport things and tossed the CO2 into the sky. We encouraged everyone to fly everywhere, and tossed the CO2 into the sky. We have known about the problems of emitting CO2 for more than 100 years. The Club of Rome commissioned a study by Jay Forester, and pollution was part of the scope. President Johnson raised the issue in the 60s. As a chemical engineering student in the 70s, I was expected to understand the topic in some detail, but industry was not paying much attention to the issue. In 1990, the IPCC set about to prove that CO2 was not an imminent problem. In 2007, the IPCC told us the Arctic sea ice would last at least to 2100, and in fact, since then we have seen significant retreat of Arctic sea ice.

This raises doubts as to the quality of IPCC models. there are the obvious issues of the models not addressing ice dynamics and carbon feedbacks. There may also be deeper issues where the science is expressed in differential equations and at the modeled grid level, the domain become discontinuous in ways not fully addressed by the "solvers".

So here we are in January of 2015, with many new disclosures of GIS melt mostly relating to the 2012 season at the SF AGU conference. However, on Christmas day after the conference, there were places on Greenland seeing 50 knot winds at temperatures above freezing.

That brings us to :

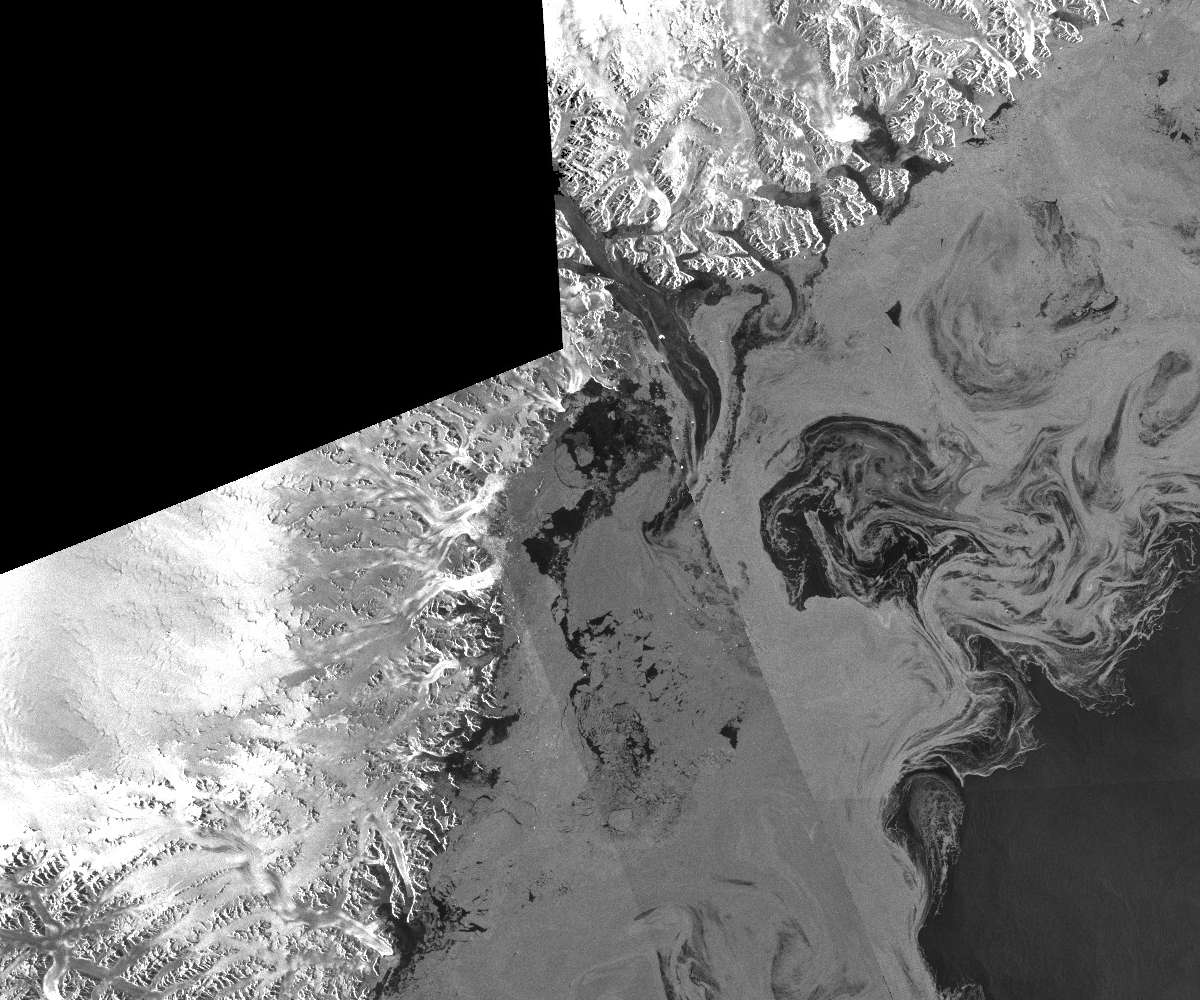

Which shows today's Kangerlussuaq Sentinel-1 2015-01-16 image (http://ocean.dmi.dk/arctic/images/MODIS/Kangerlussuaq/20150116s01a.ASAR.jpg) including outfall from fjords and melt in the Greenland sea.

Unfortunately, the 2012

Greenland melt season was a powerful clue that we can start expecting increased

melt events on Greenland, ultimately resulting in ice collapse events that

suddenly raise sea level. These are driven by the CO2 tossed into the air by the Captains of Commerce and their clients.

For a hint, look at the glacier calving event

shown in minute 64 of the movie Chasing Ice. (also at https://www.youtube.com/watch?v=hC3VTgIPoGU

) Opening up the fjord allows ice to then slide in from both sides,

and repeat the process for rapid export of ice from the ice sheet in to the

ocean. However, an ice/water slurry can also flow down a 2% grade, and an

ice sheet can contain enough potential energy to rapidly convert large

volumes of ice into an ice/water slurry as part of progressive

collapse.

In the last interglacial

period, sea level rose ~ 40 feet in ~500 years, and this rise may have been

concentrated in a few brief events. Now, climate forcing is much greater

than the gentile orbital forcing of that period, so I see no reason why sea

level rise in the next several decades could not be much more abrupt than in

the last interglacial.

Abrupt sea level rise will

destroy infrastructure/capital, resulting in a loss of capital beyond insurance

and financial hedging. It will also ensure the stranding of large amounts

of fossil fuels, and the infrastructure to extract fossil fuel. This will

be a blow to the balance sheets of corporations and their owners. It will

change our view of fossil fuel use, such as for air travel, resulting in loss

of value in assets related to air transport and travel. (And, a great

many air ports are near sea level.)

Some of the first affected

industrial facilities will be the petrochemical plants in the South Pacific

which produce the gray plastic used around the world to bed microprocessors,

and which are near sea level. Thus, abrupt sea level change will affect all

electronics including cell phones, internet, industrial control systems, and

even autos, trucks, and tractors. Loss of Malaysian petrochemical facilities

means that there are not repair parts for farm tractors - anywhere.

The local blacksmith cannot make microprocessors, and just in time production

means that there are not warehouses of parts/ microprocessors stockpiled around

the world. This was proven by loss of global Toyota production after

the Fukushima Tsunami, and loss of global hard disk drive supplies after local

flooding in Bangkok. Just in time manufacture has changed the nature of

industrial dynamics.

Many of the industrial

facilities that produce fertilizers and pesticides are near sea level, and

today most farmers (even the Amish) have lost the skills necessary to grow

large amounts of food without industrially produced fertilizers and

pesticides. Without food, people starve and stop working. Without

labor, most capital is worthless. The Koch brothers do not know how to

operate the equipment in the mines that they own. Without labor,

stock certificates are just paper. Economics has forgotten what

famine does to an economy, even a capital based economy. These

days, we assume that we can import low cost labor and food from somewhere else,

but global warming is – global. There is nowhere else to get labor, and

the food to feed it.

These days we do not maintain

large stockpiles of food – we produce it just in time. One bad harvest,

and we have surges in the price of food. (Consider the current price of fresh broccoli! At the end of last week, one local market had it priced at $5.99/ lb!) Since the rich and the poor bid

for the same food, the poor may get priced out of the market. A couple of

years ago a surge in the price of soybeans caused workers at Malaysian

petrochemical facilities to leave and seek food in their home villages.

Management stepped in and subsidized food costs and work resumed.

However, this offers a hint that a global rise in food prices could

disrupt commodity pricing in industries that depend on cheap labor. Certainly

others have looked at food price driven inflation, but AGW is very likely to

cause short crops triggering shortages and high food prices. Sea level

rise offers sustained disruption of fertilizer and pesticide production

resulting in ongoing short crops.

A few companies raising wages would merely increase bidding on scarce food stocks, making it even more difficult for some workers to buy food for their families.

Genetics tells us that

previous periods of climate change over the last 3 million years resulted in

losses in hominid populations of between and 95% and 99% . Current climate

change involves much higher rates of forcing, so I expect proportionately higher

loss of population. Experience with the Black Death in the textile

industry circa 1400 warns us that it is difficult to maintain an industry

during periods of population loss. Today all of our industries are so

interconnected, that the failure of one industry is likely to take down other

industries. That is the failure of plastics takes down

microprocessors. Failure of microprocessors takes down production

of tractor parts. Failure of tractor parts takes down agriculture. This

is not storm flooding that recedes after a day or two, it is flooding that is

sustained and increasing. It is something we have not seem before, and thus

something that most cannot imagine. Failure of agricultural crops causes workers in industrial centers to move into

the country seeking food. That is, diversity of portfolio is not likely to

ensure retention of wealth.

In short, we can take climate

change to be a massive tax on wealth. It was foreseeable. And, the

rich brought it on themselves, in that they aggressively marketed consumption

of fossil fuel as a desirable activity. The owners and managers of

corporations did not pursue sustainability. Issues were raised circa 1970 by

the Club of Rome, and then promptly ignored. Limits to Growth was

thought to be wrong when plastics were substituted for metals and metal’s

prices did not rise as expected. However, the substitution of plastics

for metals resulted in a more fossil-fuel-energy intensive economy, that

emitted more CO2 into the atmosphere. The production of CO2 associated

with plastics was real economic cost, that was not recognized at the

time. Thus, the real net cost of metals, and metal’s substitutes (i.e.

plastics) did increase. The real net cost of substituting plastics

for metals is greater concentrations of CO2 in the atmosphere, and will be

expressed as damages from AGW.

What most people see as

wealth and capital, I see as a borrowing (debt) against future environmental

conditions. The cost and penalties of such borrowing far exceed the

value derived from the borrowing, and those costs and penalties exceed anything

the borrowers or society as a whole can imagine. The rich have few skills

suited to an economy of limited capital. On the other hand the poor, have

skills for dealing with limited capital. I expect a certain reversal of roles

between rich and poor, in a period of AGW.

The accounting offered by the

IPCC is funded, reviewed and approved by the same governments that condoned and

facilitated emissions of CO2 into the atmosphere. My guess is that

governments would prefer to avoid panic(s).

The bottom line is that the curves in Capital, do not reflect the real net costs of increased

concentrations of CO2 in the atmosphere. Payback will be taken from

physical capital and infrastructure. This will hurt everyone, but it will

hurt the owners more.

A modern farmer may control millions of dollars worth of capital, but if he has a home garden, he uses industrially produced fertilizer and pesticide. A commercial farmer is not likely to have the skills to raise adequate food for his family without commercial fertilizers and pesticides. The organic gardener, with the skills to produce food without commercial fertilizers and pesticides, is not likely to control millions of dollars worth of capital. The poor will have more food.

Can the rich by that food? With what? Under such conditions, food is the ultimate trade good. Suddenly the organic gardener with skills, a spade and a hoe is the rich one.

However, the skills to make warm, durable, clothing do also have value. Now, you know why I am so interested in basic clothing.

Now, you know why I wanted a faster spinning wheel

.jpg)